Services

We offer a wide range of testing and analysis services globally.

Lubricating Oil Analysis

Optimal equipment performance starts with consistent machinery fluid testing and analysis. The Bureau Veritas global network of state-of-the-art testing facilities provides accurate, reliable results you can depend on to keep your machines up and running.

Coolant Analysis

Cooling system problems can potentially reduce the life of components within all machine systems. That’s why our coolant analysis programs focus on this vital system’s role in overall engine health and achieving optimum machine performance and longevity.

Fuel Analysis

Fuel costs and consumption are the most obvious, direct overhead factors, but operating with aged or contaminated fuel affects the short- and long-term reliability and performance of your equipment as well. Monitoring changes in fuel properties and contaminants and verifying delivery specifications can prevent costly failures and unexpected downtime.

Grease Analysis

A large percentage of component bearings are lubricated with grease, which consists of base oil, a thickener and additives. The base oil can have a mineral, synthetic or even vegetable origin. Testing ensures that all three are working together so that the grease is providing maximum metal protection.

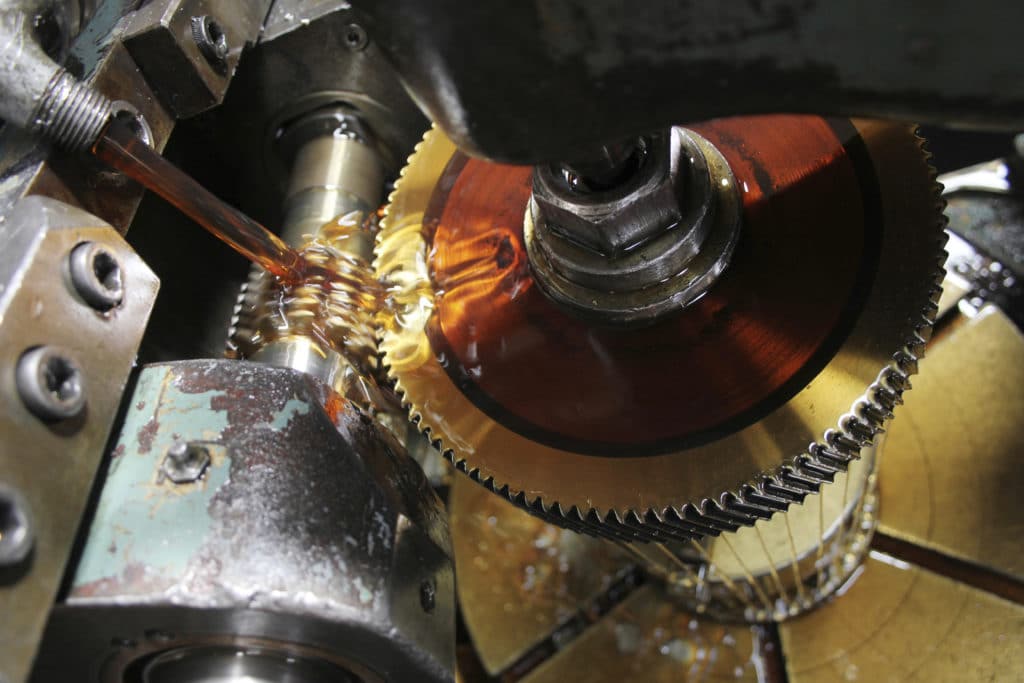

Metalworking Fluids Analysis

Bureau Veritas’ metalworking fluids analysis programs help our customers maintain high standards of product quality, improve equipment reliability and extend tool life.

Refrigerant Analysis

Bureau Veritas’ testing and analysis services are designed for routinely monitoring both HVAC fluids and system components to identify moisture build-up, wear particles and the harmful acids that can jeopardize system efficiency.

Transformer Oil Analysis

Transformers can self-destruct if neglected over time and failure to conduct regular transformer oil testing can allow problems to go undetected.