Applications

We test oil, fuel and coolant globally, to keep industries profitable.

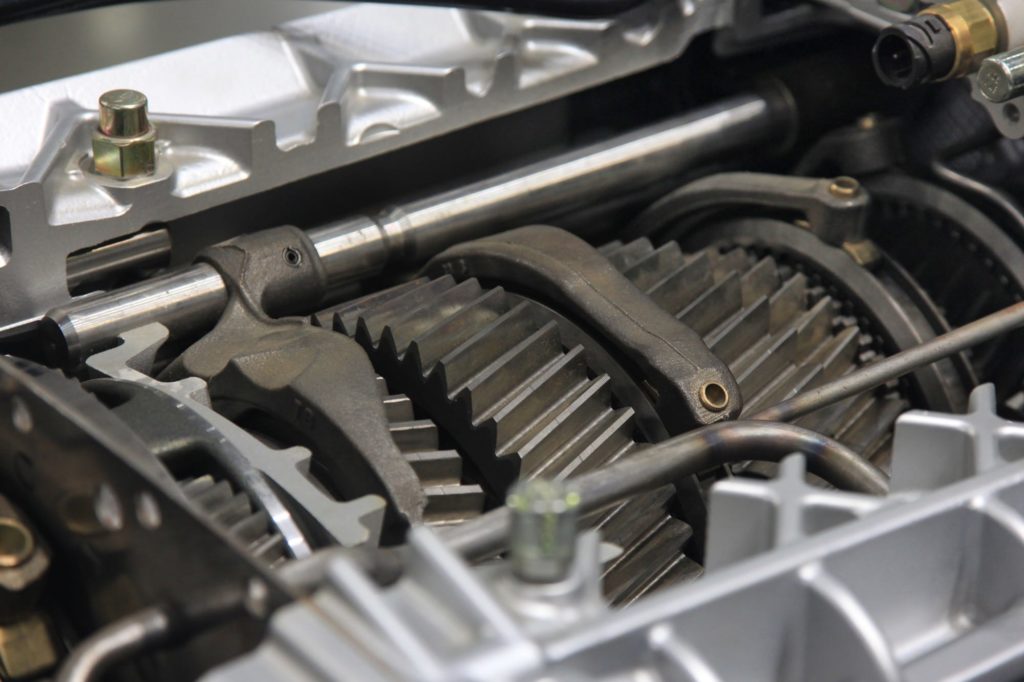

Gearboxes

Gearboxes are prevalent in numerous applications. They are all often critical to production and can prove very costly in the event of unplanned downtime and the associated losses in productivity. Oil analysis helps in preventing gearbox failure.

Pumps & Compressors

The amount of testing and analysis done on pumps and compressor systems in industrial applications is often dependent on how critical these components are to production. Routine testing and analysis can predict and prevent premature equipment failure.

Bearings

The wearing of metal surfaces, caused by various forms of contamination, can cause adverse effects in bearing systems. Implement a reliable oil testing system, improve equipment reliability, and save money in spare and replacement costs.

Engines & Generators

Engines and generators are utilized in multiple applications – ships, locomotives and numerous facilities – and situations that require back-up power. Some run continuously and others only rarely. An effective, well-implemented oil analysis program will optimize operational health and ensure equipment reliability.

Hydraulic Applications

Hydraulic systems operate under extremely close tolerances which demand a high level of fluid cleanliness. System contamination and the resulting wear conditions are the number one priority. Undetected, the presence of water can be critical to machine health and reliability.

Turbines

Turbine oils are typically expected to last 10-20 years. Monitoring in-service turbine oil condition for deterioration and degradation can significantly extend the life of both the lubricant and the turbine. Take action and implement a reliable turbine oil condition testing system.

HVAC & Refrigeration Systems

Bureau Veritas designs test packages that routinely monitor both HVAC fluids and system components to identify moisture build-up, wear particles and the harmful acids that can jeopardize system efficiency. Take action and avoid costly failures and unplanned downtime.

Stored Fuel

Fuels stored for more than six months are subject to aging degradation – oxidative products, condensation buildup, microbiological growth – and should be periodically tested to ensure reliable, satisfactory performance if used in systems that do not run continually. Take action and implement a preventive fuel handling program.

Metalworking Fluids

Bureau Veritas designs metalworking fluid testing programs for both metal-removing and metal-forming applications, where high-speed, high-production and high-friction operations make lubricity and cooling critical. Take action and increase the reliability, longevity, and profitability of your equipment.