Mobile Applications

We test oil, fuel and coolant globally, to keep industries profitable.

Diesel Engines

The biggest concerns in maintaining diesel engine health are wear and contamination. An engine oil’s four worst enemies are dirt, soot, fuel dilution and glycol, or engine coolant. Routine testing and analysis can pinpoint small problems before they become big failures.

Hydraulics

Hydraulic systems operate under extremely close tolerances which demand a high level of fluid cleanliness. System contamination and the resulting wear conditions are the number one priority. Undetected, the presence of water can be critical to machine health and reliability.

Stored Fuel

Fuels stored for more than six months are subject to aging degradation – oxidative products, condensation buildup, microbiological growth – and should be periodically tested to ensure reliable, satisfactory performance if used in systems that do not run continually. Take action and implement a preventive fuel handling program.

Coolant Systems

Bureau Veritas laboratories understand the demands today’s engine designs have placed on the cooling system to absorb heat transferred from engine, transmission and hydraulic fluids. Cooling system problems can potentially reduce the life of components within all machine systems.

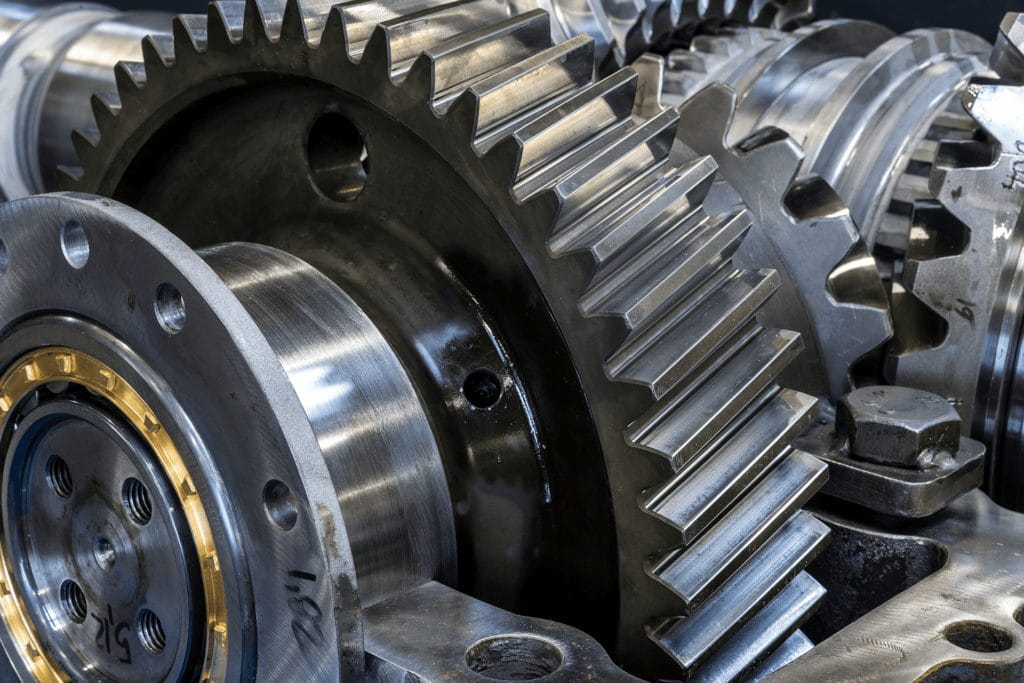

Transmissions & Differentials

Implementing a routine oil analysis program to monitor transmission wear and contamination can prove to be an extremely viable means for preventing gearbox failure, reducing downtime and controlling maintenance costs.