We rely on critical assets such as equipment, instrumentation, and various types of machines to help us increase productivity in our daily activities. To keep these assets running at peak performance, it is imperative to implement a condition monitoring maintenance plan that includes the understanding of lubricants.

The viscosity grade is a vital property of a lubricant and ensures the proper function of every component of the asset. In fact, the viscosity grade is one of the most important specifications in the owner’s manual. If a different viscosity grade is used from the manufacture recommendation, it can void the warranty resulting in significant costs, including non-productive time.

There are however some cases when using a different viscosity grade is unavoidable, and running the wrong oil is preferable than running on no oil at all. If this happens, it is important to perform an oil change as soon as possible and closely monitor the unit for changes in operating conditions.

The market is saturated with a large number of lubricant manufactures and numerous brands/labels, and can often be confusing. The various options have different bases stocks, chemical formulations, different grades, and other factors. All these factors should be considered when refilling or replacing a lubricant to mitigate costly downtime. It is important to note that not all lubricants are compatible when mixed, and mixing different lubricant bases (mineral, synthetic, etc.) and prolong use could be catastrophic.

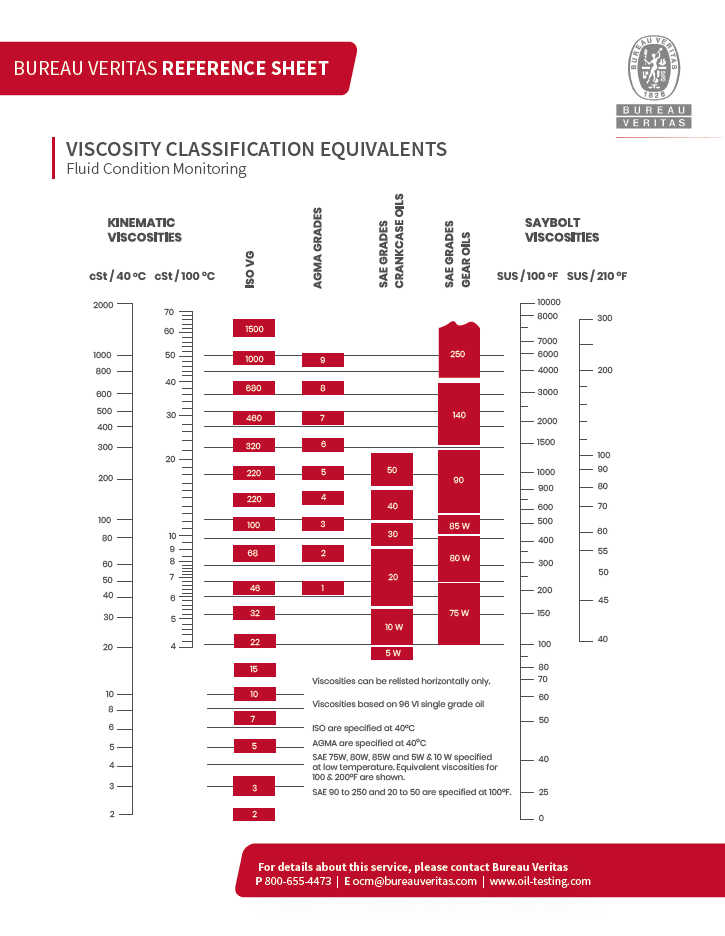

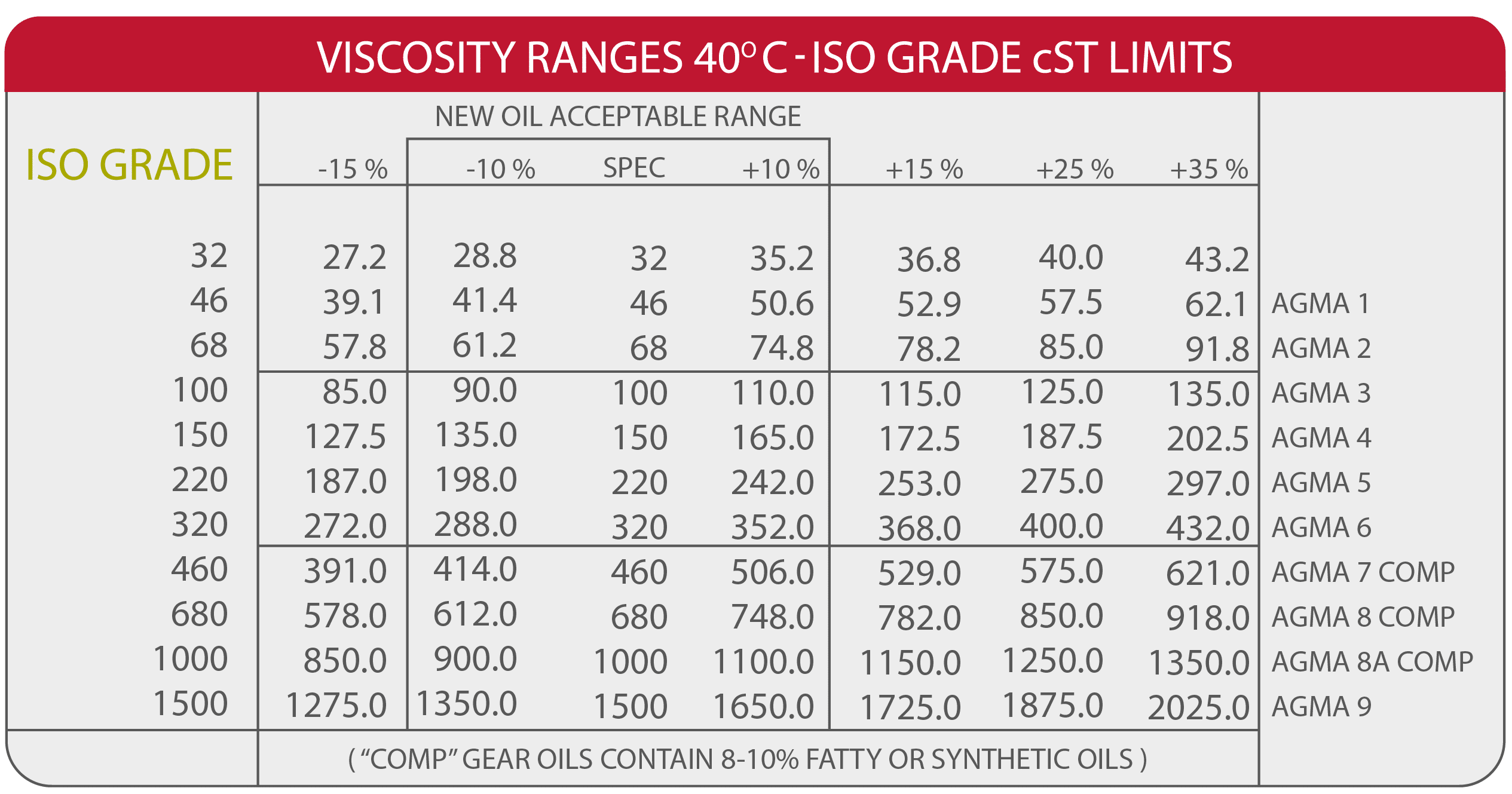

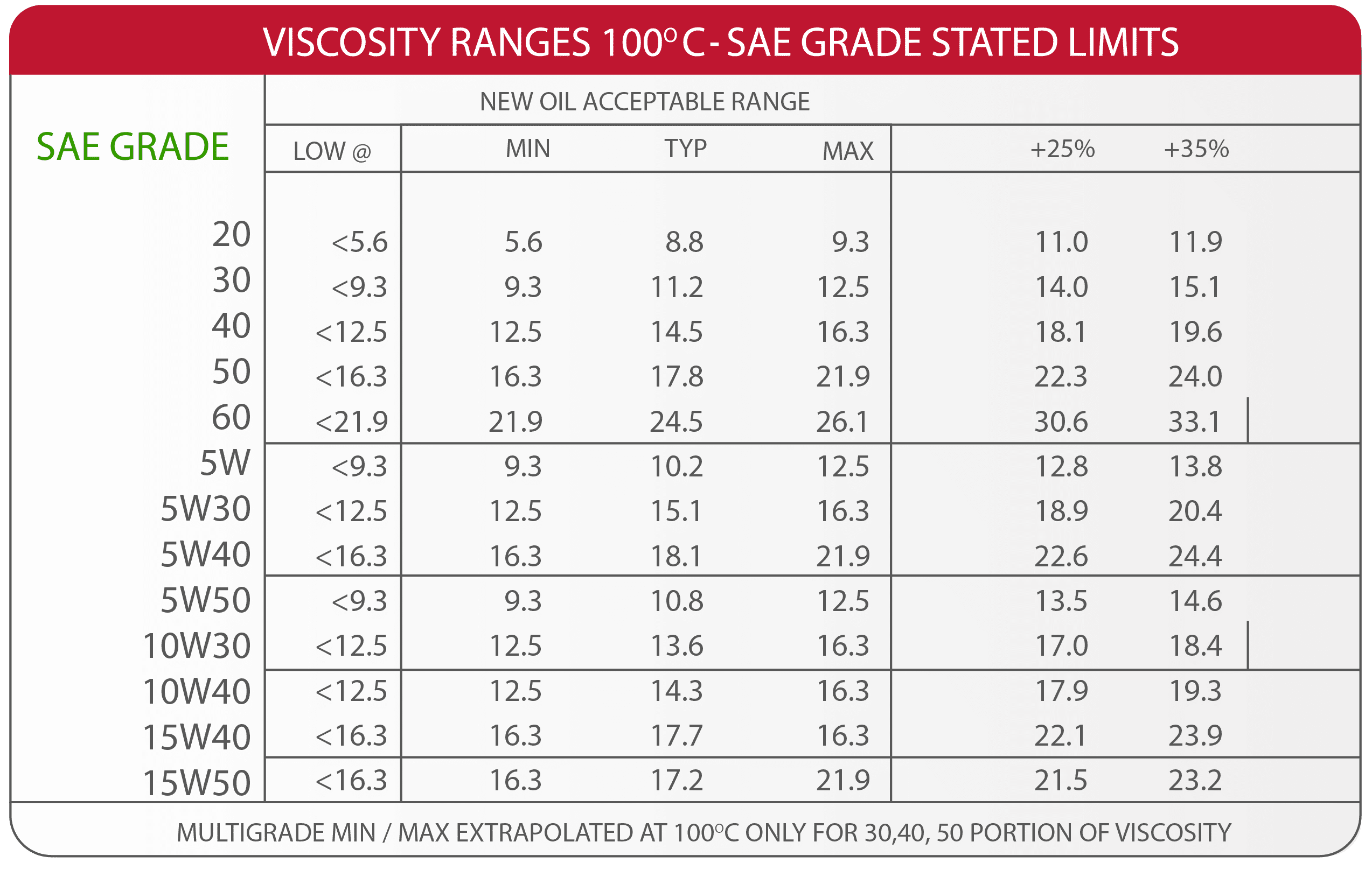

There are different standards and classifications depending on the lubricant application such as, AGMA (American Gear Manufactures Association), ISO (International Standards Organization), SAE (Society of Automotive Engineers) which has two sub classification SAE-Crankcase Oils and SAE-Gear oils. For most applications, it is common to find mono-grade lubricants (designed to work on a smaller temperature variant) or multi-grade lubricants (designed to work on a wider temperature range for winter and summer applications). Multi-grade viscosity grades are highly recommended for cold starts, such as engines or outdoor equipment that constantly work in cold elements.

The chart representing the kinematic viscosity of the lubricant is the measurement of a fluids resistance to flow under the influence of gravity. The reference point for the kinematic viscosity is pure water and it is equal to 1 cSt @20 C. This means that lubricants are many times more viscous than water. The typical standard temperature for kinematic viscosity of lubricants conveniently is measure at 40°C and 100°C depending of the grade and application

Knowing the lubricant currently in use and its basic characteristics will help to determine when to perform an oil change and what kind of lubricant used to tap off if needed. When the lubricant condition changes, the visual appearance drastically alters and usually indicates there is something wrong in the component. If not corrected as soon as possible, it can get worse or possible shut down.

Pressure and temperature can also effect viscosity. When pressure increases, the viscosity increases; and as the temperature rises, the viscosity decreases. Therefore, the viscosity of oil in service varies with temperature and pressure.

Viscosity changes can also occur due to contamination (fuel dilution, coolant and water intrusion, fuel soot, etc.), degradation (additives depletion acidification, sulfur content, etc.), thermo-degradation (thermo-cracking) and overextended drain intervals.

Implementing an oil condition and monitoring plan is extremely important in maintaining the performance of every unit to mitigate all the factors that can adversely affect the viscosity. An expert oil condition and monitoring plan helps ensure critical assets run at peak performance—delivering increased efficiencies and productivity.

Written By:

Jair Sosa

Data Analyst

Bureau Veritas - Oil Condition Monitoring

![86 [Converted]-01 86 [Converted]-01](https://oil-testing.com/wp-content/uploads/2020/09/86-Converted-01.png)