DATA CENTERS - OVERVIEW

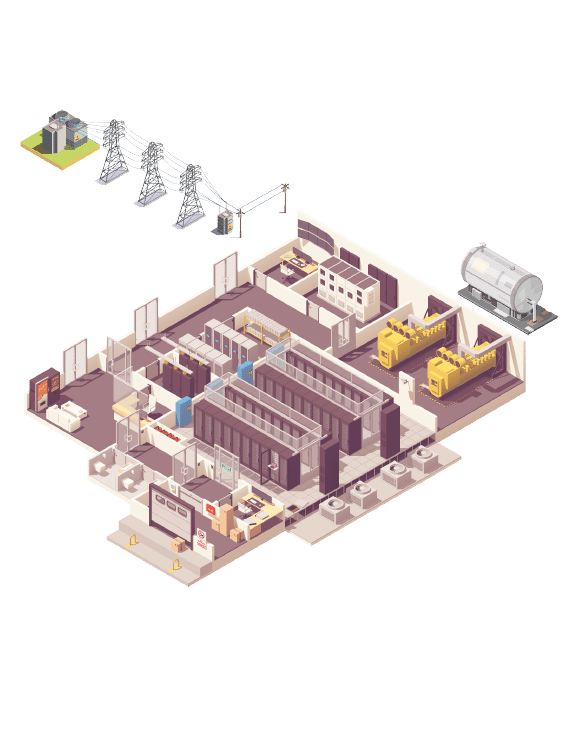

We are in a time of duplicity, a part of our life develops in a habitual way in what we consider to be the physical world, but we find another part that in some cases consumes us much more time and to which many people dedicate more time than to physical part. Many of our activities, memories and ideas are stored in an ethereal space called a cloud but what is the cloud? Where is it? And what implications does it have on a global level?

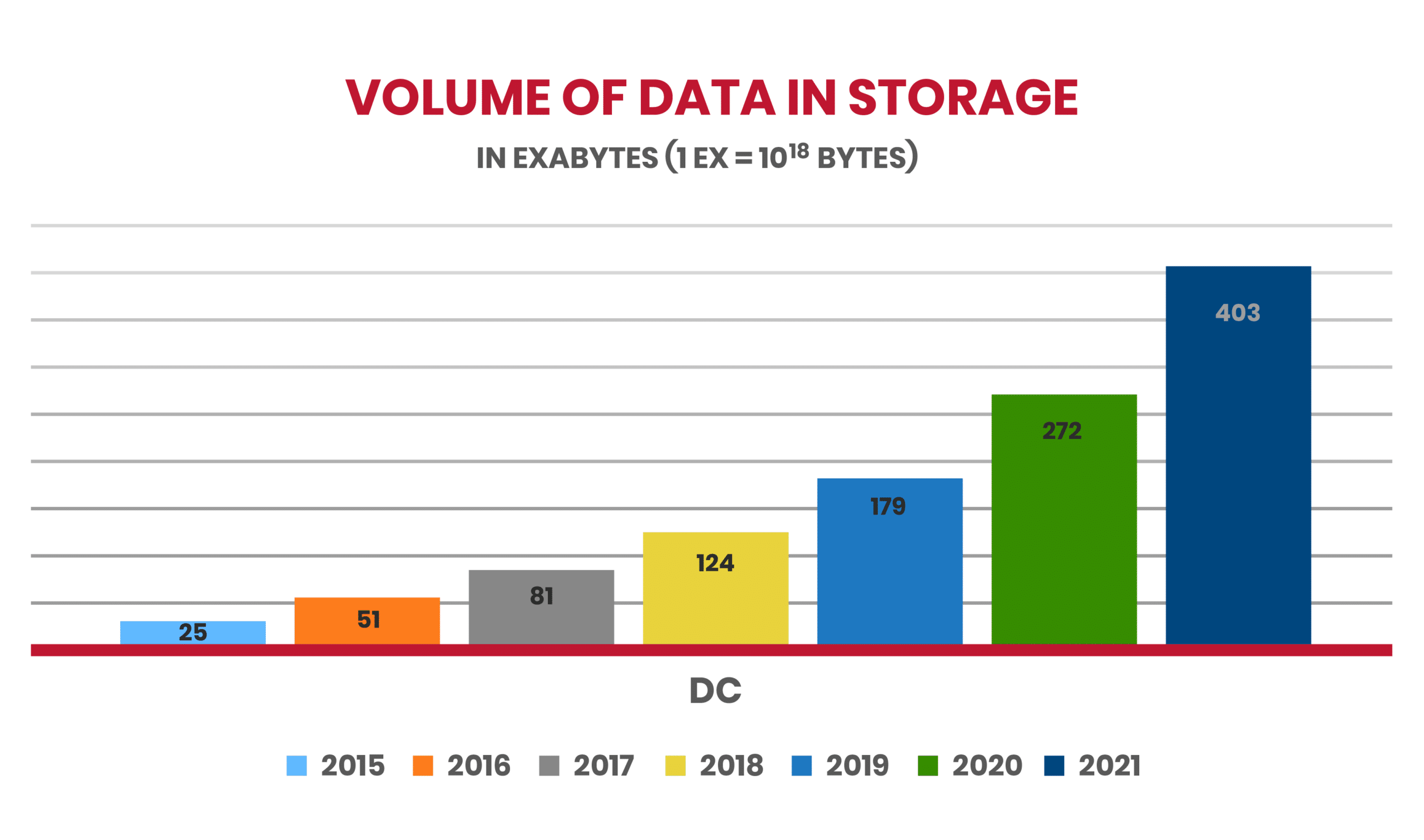

Source: Cisco Systems Inc.

The Cloud is a model of computer data storage where the digital information is kept in logical pools (a collection of resources that are ready to use). The physical storage spans multiple servers (a server is a piece of computer hardware or software that provides functionality for other programs or devices), and the physical environment is typically owned and managed by a hosting company.

Any individual or company can buy or lease storage capacity from the hosting company even directly or indirectly and the actual market size of 5.5 Billion USD will grow to a 20 Billion USD in the next five years with a wide portfolio of clients of which the most important are Healthcare, Retail, Manufacturing, IT and Financial sectors.

The need to reduce IT system downtime joined with the lack of scalable IT infrastructure, has led to a major increase in the data center services market. Similar to some primary industries, the costs for data center downtime is high, and at the same time the loss of business. Data center failures are expensive and potentially catastrophic, due to business disruption and lost revenue. The best example of this situation happened in June 2018, due to a downtime on the Visa data center caused by a switch failure, 5.2 million transactions were lost with the consequent loss of economic benefits that this may entail. One of the main objectives of the hosting company is to keep the data available and accessible 24/7 and maintain the facility running. Like any other industry, the DC depends on the supply of electrical energy to maintain and give life to its business. The main power source comes from the public network but each center needs some backup equipment to generate electrical energy in case the main source in case the main source is lost. Due to their importance to the business, these equipment must be constantly preserved and maintained.

TRANSFORMER OIL ANALYSIS

The analysis of insulating oils provides information about the oil, but also enables the detection of other possible problems, including contact arcing, aging insulating paper and other latent faults and is an indispensable part of a cost-efficient electrical maintenance program.

STORED DIESEL FUEL ANALYSIS:

Testing the diesel fuel in standby power generators is critical for the reliability of facilities to operate in the event of outside power loss. Our testing complies with NFPA 110 and ASTM D975 for determining the serviceability of on-site stored fuel.

OIL & ANTI-FREEZE TESTING:

Emergency and standby generators must work when you need them, failure is not an option. Lubricants and coolants used in standby generators will degrade over time. If not managed properly this can result in unexpected generator shutdown, operational disruptions and costly repairs. Our testing accesses the condition of the oil and coolants in your emergency and back-up power generators as part of your facility’s asset condition monitoring program.

INDUSTRIAL COOLANT TESTING:

From refrigerants to cooling water, data center cooling systems are fundamental to facility operations. Testing these fluids on a routine basis ensures your equipment never overheats.

As in any industrial application, fluids are an intrinsic part of any equipment, and this is where Bureau Veritas’s mission takes on great relevance. While the goal of data center operators is to bring the data center back up to operation as quickly as possible, fluid condition monitoring services ensure your back-up systems are available when needed. Analyze industrial fluids to determine if they are under adequate working conditions will allow the production process to maintain its normal course. The most common fluids in this scenario are Diesel, antifreeze and lube oil for the generators; turbine oil if the energy is produced in-house, stored and new fuel, refrigeration oil and refrigerants; cooling water, coolants and transformer dielectric fluids.

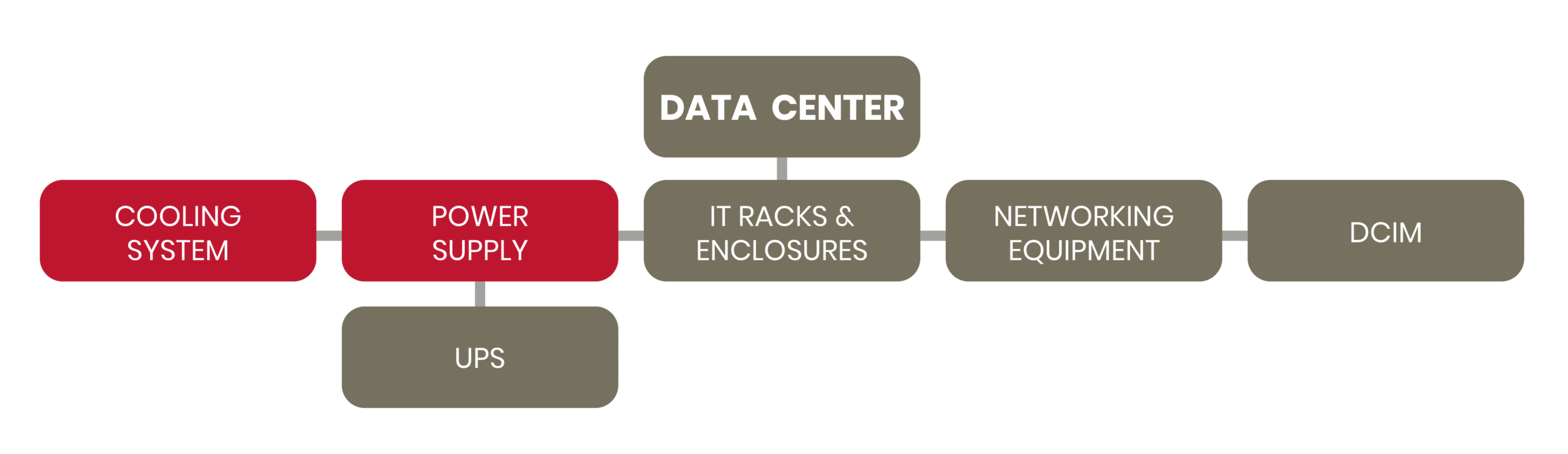

DATA CENTER ARCHITECTURE

How it could be otherwise, today intelligent systems have occupied a highly relevant place in the areas of business administration. Many DC's have intelligent systems that help to reduce energy consumption and maintain Power Usage Effectiveness (PUE), this type of software allows operators to monitor, measure, and control the most important data center parameters, covering not only IT equipment but also supporting critical infrastructure elements like cooling and power systems. It helps data center supervisors to achieve maximum energy efficiency and avoid equipment failure that leads to downtime.

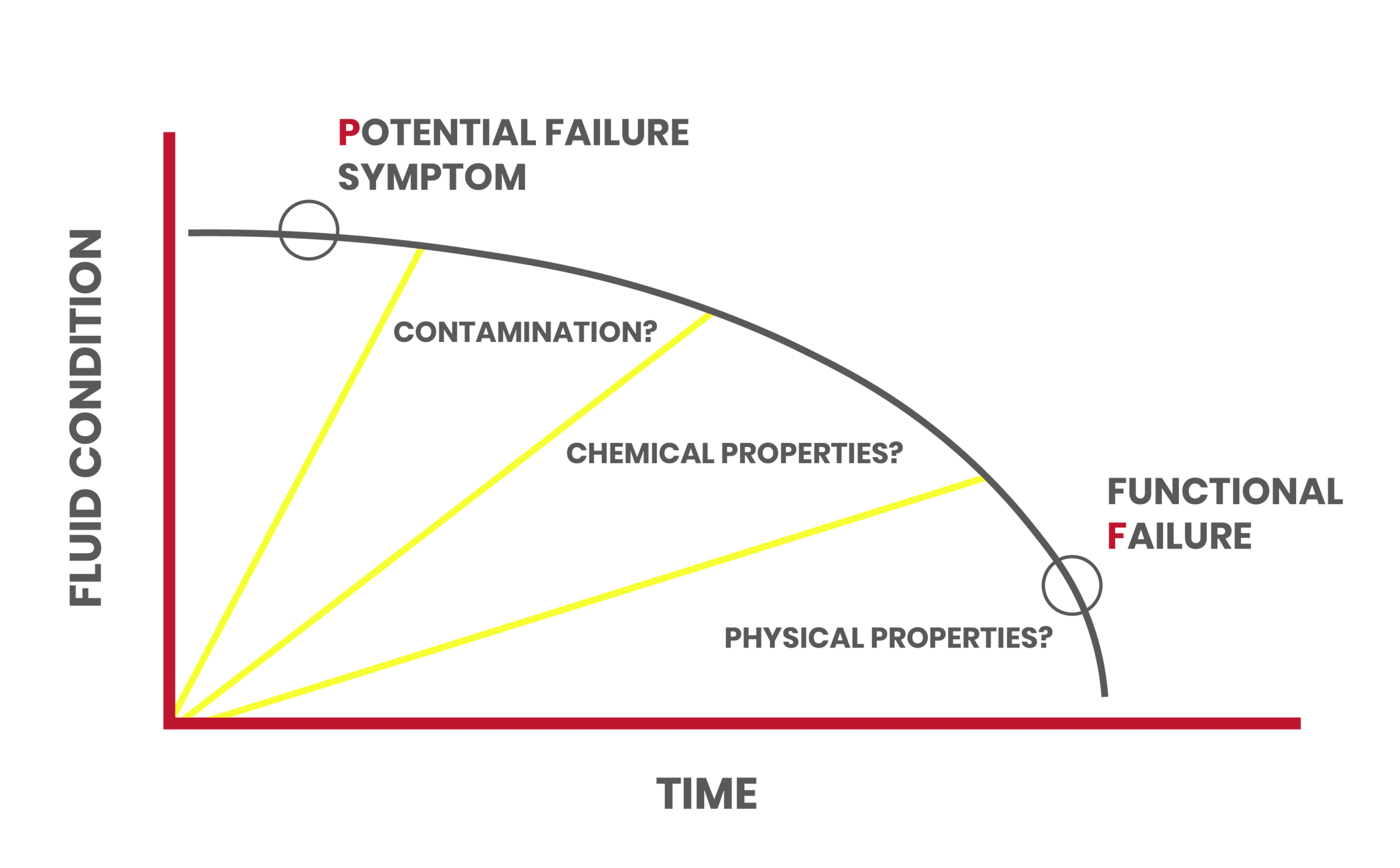

Bureau Veritas’ fluid condition monitoring services provide a complete range of testing to access the condition of the oil, fuel, and coolants in your back-up systems. Condition monitoring by Bureau Veritas helps ensure that your mission-critical systems are continuously available. Although the issue of quality and control is a good reason when analyzing fluids in a DC, one of the most important ones lies in determining the failure mode of the fluid and being able to anticipate it.

A recent study by the Uptime Institute, calculated the cost of downtime, approximately 33% of all incidents cost enterprises over the USD 250,000, with 15% of downtime episodes costing more than USD 1 million. Therefore, ensuring the physical safety and appropriate operation of each equipment, fluids, and other critical equipment, has emerged as the top agenda for the custodians of infrastructure and operations.

From the reliability and maintenance perspective the well-known P-F curve applies not only to critical machines and components but to industrial fluids. Like any other industrial element, the oil, diesel or coolants can be susceptible to failure and therefore the determination of the point where they meet is highly critical.

Fluid analysis of this critical equipment is a cost-effective way to understand the condition of the data center equipment and the fluids in them. Using fluid condition monitoring as part of the data center power and cooling systems preventive maintenance strategy ensures protection against downtime risk. For example, testing the storage diesel fuel in power generators is critical for the reliability of facilities to operate in the event of outside power loss. Bureau Veritas testing complies with NFPA 110 and ASTM D975 for determining the serviceability of on-site stored fuel.

In 2017 Bureau Veritas acquired industry leader Primary Integration (PI), expanding its services to data centers in over 140 countries worldwide. Bureau Veritas has a global footprint of technical capabilities which supports PI’s mission of providing clients with technical services anywhere in the world. This global service capability provides our clients with a value proposition that is truly unparalleled in our industry.

Written By:

Jorge Alarcon

Senior Technical Manager

Bureau Veritas - Oil Condition Monitoring