Quickly identify equipment-specific issues.

Contamination, wear and fluid degradation are the most common causes for equipment failure and the top three reasons for monitoring both fluid and equipment condition.

- Track the generation of wear metals, dirt ingression, fuel dilution and coolant leaks – the biggest concerns for engine health in heavy duty applications

- High cleanliness standards, extreme operating conditions and high replacement costs make the monitoring of acid number, viscosity and particle contamination necessary in many industrial applications

Together, the management and diagnostic reporting capabilities in LOAMS give users quick access to comprehensive data that can elevate a fluid analysis program to higher levels of performance. Documenting the cost savings from an elevated oil analysis program can justify the maintenance budgets necessary for successfully managing a world-class oil sampling program.

Technical Support

- Help icons on each menu tab explain the tab’s functionality

- Quick Links give users access to detailed training videos, quick start guides and frequently asked questions

- The LOAMS Help Desk is available to demonstrate LOAMS features or answer at 1.800.655.4473 or loams@analystsinc.com.

More LOAMS Features & Functionality

|

Equipment & Sample Report ManagementMaintain clean equipment lists, submit samples and print jar labels online and create custom search filters. |

|

Management ReportsCompile a comprehensive view of all oil analysis program data generated. |

|

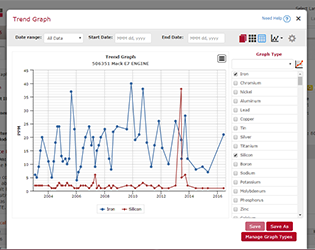

Trend GraphingChart sample conditions, pinpoint trends and compare unit and component performance. |

|

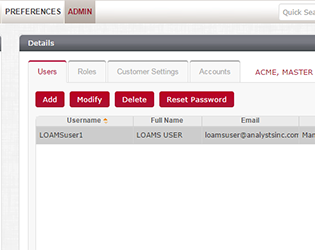

System Configuration & AdministrationUser roles are defined by permissions which determine what individual users can and cannot do in LOAMS. |

|

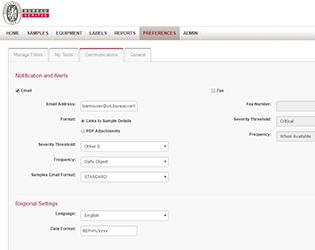

Communications & DistributionsUser preferences determine how and when information is received, how it’s displayed and how you can communicate it with others. |