Compile a comprehensive view of all oil analysis program data generated.

Fluid analysis only saves you money if you are saving equipment. The management reports within LOAMS provide a comprehensive view of all the data your oil analysis program generates.

- Document program strengths and eliminate weaknesses to elevate overall program performance

- Know that oil samples are shipped to the laboratory as soon as they are taken

- Monitor sample transit time to pinpoint issues that could be slowing turnaround time and costing you money in delayed maintenance action

- Enforce compliance with required sampling schedules to catch small problems in all of the components you are testing before they become catastrophic failures

- Address critical samples immediately and monitor those at lesser severities for changes in sample condition – trend analysis is key to achieving “normal” sample results across the board, which is the true measure of a successful fluid analysis program

Technical Support

- Help icons on each menu tab explain the tab’s functionality

- Quick Links give users access to detailed training videos, quick start guides and frequently asked questions

- The LOAMS Help Desk is available to demonstrate LOAMS features or answer at 1.800.655.4473 or loams@analystsinc.com.

More LOAMS Features & Functionality

|

Diagnostic ReportsQuickly identify equipment-specific issues. |

|

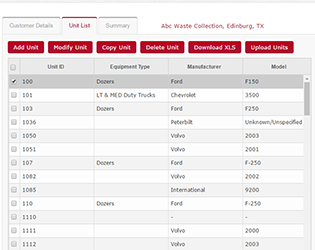

Equipment & Sample Report ManagementMaintain clean equipment lists, submit samples and print jar labels online and create custom search filters. |

|

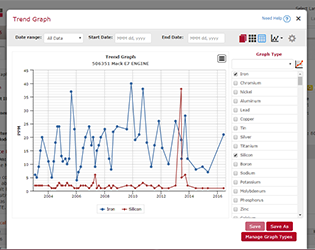

Trend GraphingChart sample conditions, pinpoint trends and compare unit and component performance. |

|

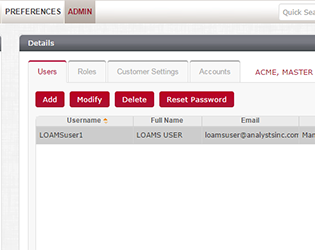

System Configuration & AdministrationUser roles are defined by permissions which determine what individual users can and cannot do in LOAMS. |

|

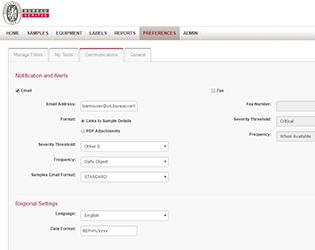

Communications & DistributionsUser preferences determine how and when information is received, how it’s displayed and how you can communicate it with others. |