Accurate, thorough and complete fluid and equipment information allows for more in-depth analysis and can eliminate confusion when interpreting results.

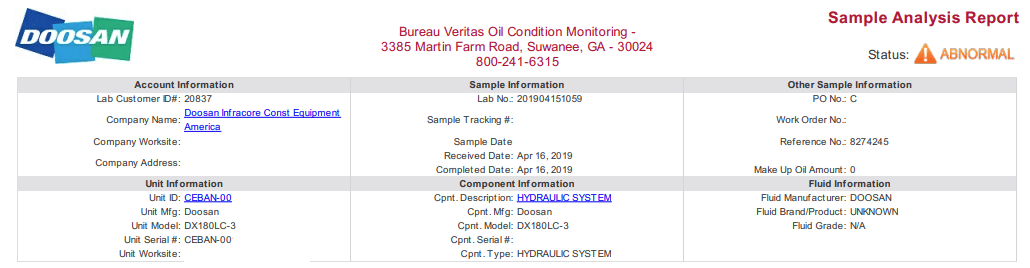

The Doosan Fluid Analysis Report

The information submitted with a sample is as important to who is reading the report as it is to the analyst interpreting the test results and making recommendations.

Properly document your equipment and share this knowledge with your laboratory. Implement a sampling process for every piece of equipment in your Doosan Fluid Analysis Program that can be followed consistently each time the unit is sampled. Accurate, thorough and complete fluid and equipment information allows for more in-depth analysis and can eliminate confusion when interpreting results.

Your laboratory’s address and your customer and equipment information are listed first.

Samples are assigned a Lab Number for easy internal tracking.

Unit ID is each customer’s opportunity to uniquely identify units being tested and their location.

Component Type should give as much detail as possible. What kind of compressor, gearbox, engine, etc., influences flagging parameters and depth of analysis. Different metallurgies require different lubrication and have great impact on how results are interpreted.

Unit Manufacturer and Model can also identify metallurgies involved as well as the OEM’s standard maintenance guidelines and possible wear patterns to expect.

Lube Manufacturer, Type and Grade identify a lube’s properties and its viscosity and is critical in determining if the right lube is being used.

All processed samples are assigned one of four Severity Codes – Critical, Abnormal, Monitor or Normal

Got a question? Call +1-800-655-4473