Taking proper oil samples that represent the actual condition of the lubricant and the component during operation is key to the reliability of both the test results and their interpretation.

To obtain oil samples representative of actual machine and lubricant operating conditions, samples should be taken at regularly scheduled intervals under normal operating conditions or within 30 minutes of shutdown. This allows for both accurate trend analysis and the proper evaluation of any change in lubricant and component condition as wear particles and contaminants will remain thoroughly mixed and suspended in the oil sample.

Areas where lubricant flow is restricted or where contaminants and wear particles tend to settle should be avoided. We recommend the following oil sampling methods and locations:

Sump Sample Port

A permanent sampling port provides a consistently accurate sample collection source and is applicable to both pressurized and non-pressurized systems.

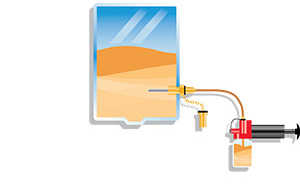

In-Line Sample Port

Samples drawn from a common return line collection point provide superior accuracy when the valve is installed upstream of the filter. This is the best sampling method for assessing machine contamination.

Sampling Procedures

Oil samples from the sump or at the reservoir drain are the least recommended methods for taking oil samples as wear particles and contaminants that tend to settle in these areas are not indicative of the concentrations present during operation.