Oil Sampling Instructions

Subscribe to our Newsletter!

Just enter your details below...

Fluid Analysis Process

Whether you are new to fluid analysis or have been practicing it in your operation for years, we can all benefit from reviewing the basics to improve our maintenance and reliability programs. Bureau Veritas has put together this six-part series to help you and your organization maximize the value you get from your fluid analysis program on each and every sample.

Taking a Good Sample

Fluid analysis is a condition monitoring tool that monitors fluid condition, contamination, and machine wear. The quality of our analysis depends 100% on the quality of the sample itself. A high-quality sample provides the most accurate representation of the machine and the fluid in it. This is the most important step in the fluid analysis process. Without a reliable sample, the whole process is compromised. Either a nonexistent problem is introduced by contaminating the sample while it is being taken or, even worse, a genuine problem is missed by not taking a representative sample.

There are three common ways to take a sample from an oil/fluid lubricated machine: through the drain port; using a drop-tube with a vacuum pump; and through a dedicated sampling port installed on the machine. While the use of a sampling port is always the preferred method, as it provides simplicity and consistency in the taking of samples, it is however not always possible. We’ve put together sampling procedures for the most common types of sampling to help you ensure you are sampling properly for your application.

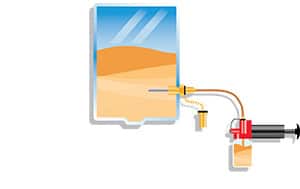

Sump Sample Port

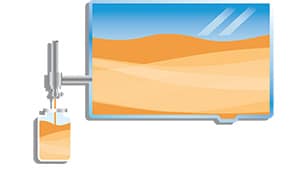

In-Line Sample Port

Sampling Procedures

Sampling Best Practice

1. Take the sample while the machine is operating, or within 30-minutes of shutdown. Do not take a sample from a cold system.

2. Take the sample the same way every time, consistency is key. Do not change where or how you are taking the sample as this introduces variables that could result in a false-positive or false-negative alert.

3. Take samples at routine frequencies based on operating hours or calendar days. Do not take samples as needed, as infrequent samples or samples taken at different intervals become subjective and difficult to build reliable trends from.

4. Ensure sampling devices are clean and free of contamination. Do not re-use sample tubes or bottles, as this can introduce contamination to the sample.

5. Send samples immediately to the lab. Do not hold samples for a long period of time before sending them to the lab.

We hope these tools and processes assist you in your maintenance journey. Our team is committed to helping you get the most out of your sampling program. If you need more assistance, contact us, and we will connect you with one of our Account Managers or Data Analysts.

Got a question? Call +1-800-655-4473